Forming Ovens

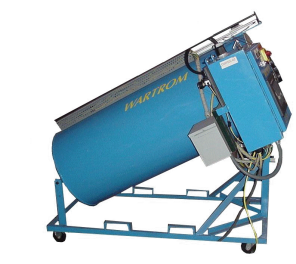

Shown here is an example of our patented Hot Process Rotary Oven, designed specifically for thermo-forming plastic and rubber hose, our Hot Process Rotary Ovens defined the way tubing and hose assemblies are formed. (Patent #: 6,310,324)

These ovens are the centerpiece of our hose forming cells along with the ferris wheel style cooling station. The oven temperature is controlled and monitored by separate controllers to ensure the temperature is always consistent inside the oven chamber, the cooling process is also controlled by the oven processor to not allow product to begin to cool too long prior to loading into the form fixture. Any delays will not allow the cooling air to be supplied to the cooling fixture.

These forming cells take up minimum floor space, are portable to move to any area of the plant where there is an air supply and electrical service. They consume minimal electricity and will accept any length tube up to maximum length per model number. The maximum OD of the tube to be formed is 5/8" diameter at this time. These cells are an economical means to manufacture formed plastic lines and can be used along with one to eight form fixtures per product instead of dozens of form fixtures that batch ovens require.

Our ovens last for many years over multiple programs saving you capital and allowing you the opportunity to be more competitive with your pricing.

Send us a sample product you would like formed and we will run trials here in our prototype oven to send back for your evaluation.