Test Equipment

Transmission Pan Leak Tester

This test station checked for all of the mounting holes present, the tapped holes clear, mounting flange formed correctly and leak tested the entire pan. If there was a failure in the leak test station the shuttle transferred the pan out the rear of the machine for visual inspection. After an accepted leak test, the pan was shuttled to the next station where it performed the remaining checks and ink-marked the accepted pan.

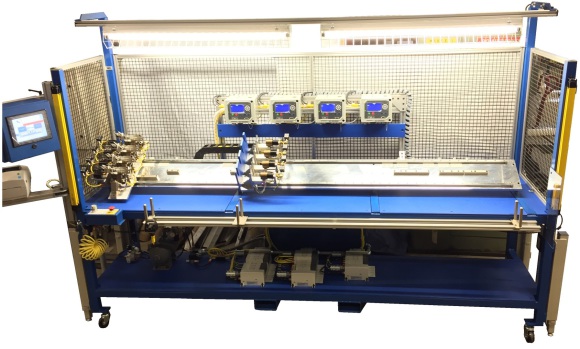

Leak Testing

This multi-station leak test fixture tests the “wet” side of the water pump, it includes quick change tooling and part selection via the operator interface. It also requires multiple stations due to required cycle time. It marks the housing after a “passed” test to verify the pump has been tested and also looks for the mark in the following station so the testing can not be bypassed. Failed pumps are acknowledged and accounted for by placing in a reject magazine, the machine will not cycle again until rejected pump is accounted for. We utilize commercial leak test units from leading worldwide providers in our equipment and have been providing test stands similar to this for over 25 years.

Multi-Part High Pressure Tester with Quick Change Tooling Plate

This is an example of our base test stands with multiple quick-change fixture plates. These stands allow for us to simply supply additional fixture plates for new products as they are released. These stands also have “reject” bins with verification of deposit. They can be utilized for many products and last many years; reducing floor space and capital investment.

Four Station Pressure Tester

This stand is a multi-station for two similar products and includes leak testing, two different cavities and vision verification of correct product present prior to testing. All test results are displayed on the interface unit and part selection is via push-button on the unit also. A paint mark is applied after “passed” condition and is verified in the following station prior to operating.

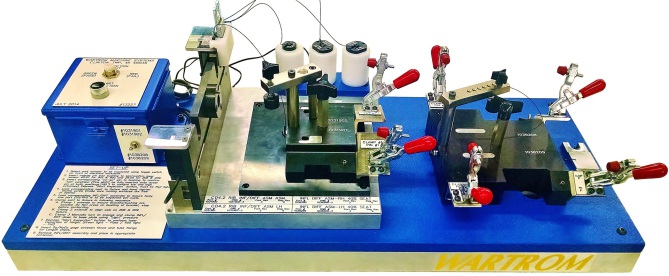

Tester with Quick Change Tooling Plate

This is an example of a multi-channel quick change tooling test stand. We have provided many of these stands that have been in operation for many years and served many programs. These stands optimize capital investments like no others. It is common that revisions to these stands for new product are customer paid tooling and will give the owner an advantage when quoting new programs.